About our company.

LOGIC Technologies, Inc. has been providing plant-floor automation solutions on an international scale for over 30 years. Fortune 500 clients throughout the United States, South America, and the Pacific Rim rely heavily on the quality and durability of our systems to maintain their respective daily operations. Our extensive experience with the design, development, and implementation of software and control solutions in a variety of industries is unparalleled.

-

dbcOS our eLOGIC dbc/OS32+ platform offers some major advantages to the customer. The platform is based on our Signal Server Technology, which interfaces real world signals into a network environment. The system allows for plant wide system control and can be customized for each customer's specific needs. The dbc/OS32+ server system provides an open architecture I/O interface that allows us to utilize the same industry standard PLC rack component systems that you're already familiar with (AB, GE, Opto22, Koyo, ect...). To date, more than 350 of these systems have been successfully implemented.Download Information →

dbcOS our eLOGIC dbc/OS32+ platform offers some major advantages to the customer. The platform is based on our Signal Server Technology, which interfaces real world signals into a network environment. The system allows for plant wide system control and can be customized for each customer's specific needs. The dbc/OS32+ server system provides an open architecture I/O interface that allows us to utilize the same industry standard PLC rack component systems that you're already familiar with (AB, GE, Opto22, Koyo, ect...). To date, more than 350 of these systems have been successfully implemented.Download Information → -

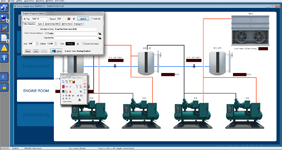

Engineering/Graphic Suite Each DBC/OS32+ server system includes a site license for our eLOGIC client application suite. This LAN-based tool is a Microsoft Windows-based application that can be installed on any Windows-based PC located in the facility. The application provides full access to the control system control panel. The client application also provides advanced graphic screen creation tools and data collection capabilities for the system.Download Information →

Engineering/Graphic Suite Each DBC/OS32+ server system includes a site license for our eLOGIC client application suite. This LAN-based tool is a Microsoft Windows-based application that can be installed on any Windows-based PC located in the facility. The application provides full access to the control system control panel. The client application also provides advanced graphic screen creation tools and data collection capabilities for the system.Download Information → -

eCube OS The eCube Operating System is designed to monitor up to twenty different sensors. Sensors such as Temperature, Humidity, Co2, Ethylene and Ammonia can be connected to the eCube. The sensors are physically wired to the individual eCube inputs for monitoring. The eCubes communicate with a remote computer for data display and alarm monitoring. Parameters such as alarm levels, On/Off setpoints and deadbands can be set up for each sensor. These values can be changed at the eCube and on the remote computer.Download Information →

eCube OS The eCube Operating System is designed to monitor up to twenty different sensors. Sensors such as Temperature, Humidity, Co2, Ethylene and Ammonia can be connected to the eCube. The sensors are physically wired to the individual eCube inputs for monitoring. The eCubes communicate with a remote computer for data display and alarm monitoring. Parameters such as alarm levels, On/Off setpoints and deadbands can be set up for each sensor. These values can be changed at the eCube and on the remote computer.Download Information →

-

Large scale systems The eLOGIC Signal Server provides SCADA class control for plant wide automation efforts. The server can communicate with various industrial input/output structures and will interface with all major brand PLC's. This connectability allows users to retrieave data, monitor signals for alarm conditions and provide supervisory control with a mix of different equipment suppliers.Download Information →

Large scale systems The eLOGIC Signal Server provides SCADA class control for plant wide automation efforts. The server can communicate with various industrial input/output structures and will interface with all major brand PLC's. This connectability allows users to retrieave data, monitor signals for alarm conditions and provide supervisory control with a mix of different equipment suppliers.Download Information → -

Medium scale systems Our eLOGIC Micro-System is designed to serve as an open-architecture NH3 screw compressor retrofit controller. The system can be configured to control the operations of NH3 screw compressors produced by all major manufacturers. Since its inception, the controller has proven itself to be a viable option for all small to medium sized control systems due to the power and versatility of the design.Download Information →

Medium scale systems Our eLOGIC Micro-System is designed to serve as an open-architecture NH3 screw compressor retrofit controller. The system can be configured to control the operations of NH3 screw compressors produced by all major manufacturers. Since its inception, the controller has proven itself to be a viable option for all small to medium sized control systems due to the power and versatility of the design.Download Information → -

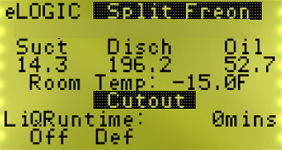

Small scale systems The eCUBE is a compact control device with enough processing power and on-board I/O to handle virtually all local area control requirements. The versatility of this small unit is unparalleled in the controls industry. While the built-in user interface defines the unit as a perfect solution for dedicated equipment control, the inherent network capabilities also make it a viable solution for plant-wide distributed intelligence designs.Download Information →

Small scale systems The eCUBE is a compact control device with enough processing power and on-board I/O to handle virtually all local area control requirements. The versatility of this small unit is unparalleled in the controls industry. While the built-in user interface defines the unit as a perfect solution for dedicated equipment control, the inherent network capabilities also make it a viable solution for plant-wide distributed intelligence designs.Download Information →

We believe your controls system provider should serve more as a trusted business partner than a vendor. This being the case, our approach to control solutions is quite different. Our philosophy is that in order to provide solutions for a customer, you must first understand the customer's unique process requirements. We do not attempt to persuade a customer to conform their daily processes to meet the specifications of a standard system. Instead, our engineers take the time to study each customer's unique process requirements.

Once the processes are fully understood, a control/software solution is developed using our core system component libraries. The extensive functionality of the core libraries allows us to quickly provide the customer with a custom solution that truly accounts for their unique business needs. The net result is a custom solution that typically costs less than the mass-produced systems that require the customer to dramatically alter their processes or operations.

Our primary focus is and always has been to provide reliable environmental/refrigeration control solutions. During the early stages of development, we realized that the data collection and historical analysis requirements of these systems could not be resolved with a conventional PLC approach. A PLC/HMI solution could obviously have been implemented; however, the resulting systems would be limited to the functionality of the HMI application suite utilized. We also had concerns about the cost associated with ever-changing propietary software licenses required to support PLC/HMI systems since that cost would ultimately be passed on to the customers. In order to solve these problems, our staff members began developing a design methodology that would provide a cost-effective reliable solution without functional restrictions. The end-result came to be known as Signal Server Technology or SST.

Although we are happy to provide standard PLC-based control systems upon request, our eLOGIC dbc/OS32+ platform offers some major advantages to the customer. The platform is based on our Signal Server Technology, which interfaces real world signals into a network environment. The system allows for plant wide system control and can be customized for each customer's specific needs. The dbc/OS32+ server system provides an open architecture I/O interface that allows us to utilize the same industry standard PLC rack component systems that you're already familiar with (AB, GE, Opto22, Koyo, etc...). To date, more than 350 of these systems have been successfully implemented.

"Technologically advanced reliable solutions at an affordable price..."